Lambretta Engine Work

General

Lambretta

|

|

Piston Install

One of the most important

parts of a well operating engine is a good piston and bore to keep

compression high and transfer that power to the back wheel. Basic

tolerances between a piston and a bore are typically 0.2mm. If you

remove your barrel and find deep scoring on the piston and bore it is

definitely time for a new piston. Pistons cost between $45 and $70

depending on what bike you are buying for. Whenever a new piston is

installed it is important to rebore the barrel to the next oversize if

there is major scoring of the surface, or at least hone it to be sure

that the wear ridge at the top is removed. The one pictured is from a

GP125 motor. The following images show the piston replacement after

removal of the old barrel and piston, and in these images the engine is

out of the frame but it is not a requirement.

- A piston kit

- A rebored or honed barrel

- Some two stroke oil

- A new barrel base and head

gasket

- Circlip pliers

- Possibly a new small end

bearing (optional)

- A set of feeler gauges

- A 14mm socket and driver

A piston kit usually comes

with the piston, two new rings, a wrist (or gudgeon) pin, and two

circlips. On the piston above you can clearly see an arrow stamped in

the top facing to the left of the image. When the piston is installed

this must be facing the exhaust.

Step 1 - Checking the ring

gap: Take either one of the rings and fit it as squarely as you can

in the top of the barrel bore. When the rings get hotter they expand

and it is critical to be sure there is enough room for expansion

otherwise there is risk of a seizure. With the piston ring in the bore,

slide the ringless piston down in the bore skirt first. This will push

the ring down in the bore and keep it square to the diameter of the

bore. I usually push it down until the wrist pin hole is about central

with the top of the barrel.

Remove the piston and get out

a set of feeler gauges. The minimum ring gap is 0.2mm. Measure this gap

by fitting a feeler gauge in between the ring ends while making sure

the ring is not in any port windows. If it is less than this you will

need to remove the ring and use a very fine file or sandpaper to

slightly increase the end gap. If it is more than this you may need to

buy new rings for your piston. Once you are happy with the gap, slide

the piston down as you did before and push the ring through the bore to

remove the ring. Check the second ring in the same manner.

Step 2 - Preparing the

piston: Before the piston is installed, the rings must be put on

the piston. Both rings are the same so it doesn't matter which one goes

on first but it does matter which side faces "up". Have a look at the

piston ring grooves and you'll see small peg in each groove shown with

the green arrow above. The peg is not central to the groove and is set

closer to one edge so that only half the peg circle extends into the

groove. Now have a look at the ends of a piston ring. If you slightly

compress it with your fingers you'll see that the same half circle

space is cut out of the ring ends.

Make sure you have the piston

ring the right way up for the groove you are setting it in. Carefully

stretch open the ring so it can fit over the piston and slide it down

the sides until it fits the groove. I usually fit the lower ring first

as it is harder to get the lower ring over and already installed upper

ring. Do a final check to make sure both rings fit well and their ends

interface with the pegs.

Above is a shot of the lower

ring correctly installed for reference. Fit the upper ring in the same

manner.

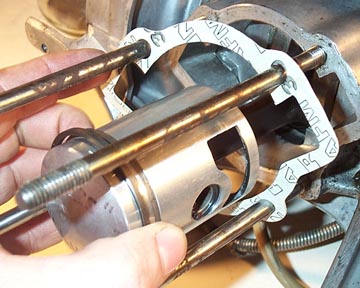

Step 3 - Installing the

piston: Fit a new small end bearing or (on older models) a brass

bushing. Use a little two stroke oil to lubricate it. The images above

are of an engine which is actually upside down from the way it would be

installed in a bike as it is easier to work on and balances itself on

the engine mounts. Please keep this in mind when following the steps if

your engine is still in the bike.

Look on the piston head for an

arrow stamped in it. This MUST face towards the exhaust port or

directly down towards the ground in a motor still mounted in a bike.

Before fitting the piston you

may need to heat it with a hot wet rag to allow the wrist pin to fit

more easily. Press the wrist pin in only far enough that it stays in

place and then take the entire piston assembly and center the wrist pin

hole over the small end hole. Carefully push the wrist pin through the

caged needle roller small end bearing and through to the other side of

the piston. When fitted correctly both sides should have an equal depth

from the pin end to the face of the piston.

Using circlip pliers, fit both

circlips to either side of the pin. Make sure they are fully seated in

the groove in the piston. You don't want these coming loose in a

running engine. Since this picture was taken I have learned more info

and all circlips should be installed so that they have the ends either

up towards the piston head or down towards the piston bottom, that way

there is no way for the clip to get squeezed by the accelertion of the

piston, and pop out.

Step 4 - Installing the barrel: Slide a new base gasket over

the piston. This gasket will only fit one way due to the cylinder studs.

Clean and check the bore for any dust or any other

contaminate. Rub some two stoke oil around the bore for lubrication.

Carefully start to slide the barrel on to the cylinder studs.

The barrel can only fit one way and goes on with the spigot (the part

that sticks out past the fins) towards the casing. Once the spigot has

come down on the piston enough to hit the first ring, you'll need to

compress the ring to get it into the barrel.

Make sure that if the rings have rotated, their ends are back

in line with the ring pegs. Carefully compress the rings with your

fingers while sliding the spigot down over the piston. Once one ring is

in the barrel you can switch to the second ring and use the same idea.

Slide the barrel all the way down over the piston and turn the flywheel

to make sure the piston travels freely in the bore.

Once the barrel is in place, and has been pushed down on to

the casing, you can install the single aluminum head gasket. This only

fits one way due to the cylinder stud layout.

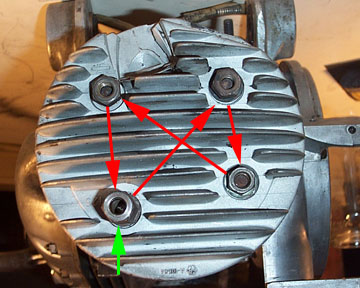

Fit the head to the cylinder studs...

...and add the washer and nut to each stud. A single stud

(shown in the next picture with a green arrow) receives the special

coupler nut that the barrel cowling bolts into. Tighten the nuts only

hand tight for the time being.

This image has been flipped to show how the head looks if the

motor is installed in the frame. Tighten the head nuts about 1/2 a turn

each and then alternate to the next one in the pattern shown above.

This system makes it very unlikely to warp the head when tightening.

The green arrow shows the location of the coupler nut.

Finally, fit the spark plug, cylinder shroud, and start the

motor up.

Note: For the first 300 miles you should drive very carefully,

do not over rev the motor, stay at low RPMs where possible, and vary

the engine RPM when stuck in any single gear because of road

conditions. Breaking in a piston carefully is the best way to ensure

long life from your top end.

A typical new piston with new rings and a rebore should

develop about 125 to 140 PSI compression which can be tested with a

spark plug threaded compression tester available from most auto parts

stores.

|

|

|